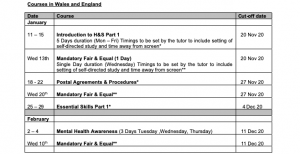

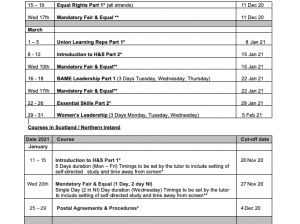

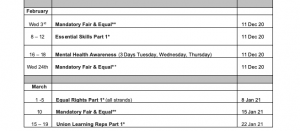

Royal Mail Materials Handling Containerisation Update & Christmas Arrangements 2020 – Health & Safety Aspects

Below is a summary update on Materials Handling Containerisation Arrangements for the 2020 Christmas period. The contents of this LTB have been discussed and agreed with Royal Mail HQ, Central Containers Team, Safety, Health & Environment Team and Head of Assets.

- York Containers

Royal Mail has purchased an additional 70,000 Mk3 York Containers and these, along with 552,000 (Mk1, Mk2 and Mk3) York Containers already in circulation since March due to the accelerated increase in Parcels into the RM Network brought on by the COVID-19 Pandemic and increase in e-commerce, a total fleet of around 622,000 Yorks will be in service during the Christmas pressure period. The 70,000 Yorks purchased is the highest volume of Yorks RM has purchased in a single year which was increased from a planned 34,000 due to the increase in parcels as a result of the pandemic. This is the largest order placed with the supplier, which took up their entire remaining capacity. No further options to fabricate more Yorks is available with any supplier. Despite this large order of Yorks there is still a 30% shortfall of Yorks for the peak period of 2020 so alternative arrangements for some customers as well as contingencies within the network are required to maintain service.

Royal Mail will be looking for Yorks to be filled with the maximum 7 layers of 4 trays (28 Max), wherever possible subject to safe systems of work, weight constraints of the container and subsequently the vehicle weight limits on to which they will be loaded to comply with Safe Systems of Work and both Health and Safety and Road Traffic Act Legislation.

York Containers primarily carry mainly stacked parcels, trays or mailbags without a sleeve or small parcels and packets in ALP (Auto-Level Packet) sleeves or cardboard sleeves.

All Mk1, Mk2 and MK3 York Containers introduced in previous years have continued to be maintained, modified and updated through rework programmes as identified by the Royal Mail Assets, Containers and Manual Handling Equipment Team in consultation with the CWU Health, Safety & Environment Department and as previously reported in updates to Branches and Area Health and Safety Reps. Mk’s 1, 2 and 3 amount to the vast majority of the 622,000 York Containers.

Of the 70,000 Yorks which have been purchased this year, 10,000 will have a variation to the base based on a MK4 base type construction.

This is purely down to production issues with K Hartwall with the injection moulding supplier they use who produce our Yellow plastic bases. Working jointly with RM and CWU it was agreed to use a proposed solution which K Hartwall are fabricating to the highest speciation at their expense to ensure our order does not impact on Christmas operations.

The bases will be swapped out for Yellow bases following peak through standardised repair flows as and when they go into service.

These are fabricated to the highest standard and meet all ergonomic requirements and in no way are any different to the operational uses and can be nested and operated in the exact same way as the Yellow bases.

Please Reference the attached document for photos – MK3 York Bases (COVID)

1(a). York Container ALP Sleeves

Royal Mail, over the last 3 years purchased 120,000 new ALP Sleeves all of which were released into the network. A further 51,000 MK1 ALP Sleeves were purchased this year to support the increase in parcels brought on by the pandemic. The Grey Mk2 ALP Sleeves, which include a modification to allow the ALPs to be automated/tipped within the Parcel Sortation Machine (PSM) Mail Centers (MCs) deployed as part a National Joint Trial as agreed with both the CWU Health, Safety & Environment Department and the Postal Department, have continued to be modified with some localized trials to improve the resting height of the bases. Trials of improved Mk2 ALP Sleeves, with uprated return springs, are underway, within a closed loop operation following joint CWU/RM discussions and feedback sessions. The outcome of the trial will be considered in due course and will conclude with the replacement of all existing (Grey) Mk2 ALPS being replaced.

1(b). York Container – Cardboard Sleeves

Although Royal Mail has centrally purchased a further 51,000 New Red Mk1 ALP Sleeves this year, as Royal Mail moves further into the busiest period at Christmas, and parcel volumes begin to peak, the need to move parcels through the network quickly becomes critical and demand for ALP Sleeves increases. Even though Royal Mail has put 320,000 additional York Containers and 300,000 additional ALP Sleeves in to the network over the last seven years, amounting to 620,000 York’s in circulation with over half of those fitted with an ALP Sleeve, Royal Mail has informed us that with increasing parcel volumes and large tracked customers there may be problems with sites struggling to get sufficient numbers of ALP Sleeves to meet their operational requirements. The Central Container Team will continue to push the Zonal Areas to ensure that they clear their Delivery Offices every day and repatriations from gaining sites take place but they may still struggle to meet the demand at key locations. Royal Mail has assured CWU/HQ that they will do everything possible to ensure that Zonal Areas repatriate as many York Containers and ALP Sleeves as possible out of their Delivery Offices however the business is now seeing the continued increase in parcel volumes and traffic accelerated through COVID-19. As a result, Zonal Areas will probably struggle to get sufficient ALP Sleeves back into their Parcel Sort Centre operations and losing Mail Centers to meet demand. As and when critical emergency situations are reached in Offices, Royal Mail has proposed and CWU/HQ has agreed that, the use of Cardboard Sleeves/York Inserts will be permitted as a last resort – with agreement with the RM CPC/Container Team as follows:

(a) As a contingency supply source at Mail Centre’s on all mail streams (including PSMs), PSCs and RDC’s for outward dispatches and inward dispatches to DOs.

(b) For outward dispatches by Mail Centers (including PSMs) and Parcel Sort Centres.

(d) Before this contingency is implemented however the site must ensure that all efforts have been made to get ALPs back from their DO’s and that permission has been sought and been given by the RM Container Team.

(e) Designated and approved Customer Streams to MC and DO (AMZ DI/DDU).

(f) To move essential PPE and cleaning supplies through to the operation.

IMPORTANT: – If Cardboard Sleeves/York Inserts are used as a contingency, the site must ensure that:-

(a) The CWU Area Safety Representative and Area Processing Representative are consulted should this contingency need to be implemented.

(b) That the SSoW is followed at all times, rotating duties if necessary.

(c) That the mandatory cross-members and false bases must be fitted and used correctly in Cardboard Sleeved York Containers. Any Offices found not to be compliant with this instruction will be asked to investigate reasons why this has happened and furnish a report on remedial action taken with the report shared with the CWU Area Safety Representative. Such breaches of the SSoW by management will be viewed as serious!

If the demand for parcels decreases, the contingency use of Cardboard Sleeve Inserts will be withdrawn and Offices will revert back to business as usual with Cardboard Sleeves used on the agreed Amazon/Tracked Contracts only and the parcel operation must revert back to using ALP Sleeves for inward transfers to DOs and outward dispatches to Mail Centres and Regional Distribution Centres.

The cardboard MUST be in good order; the cross member and base must be inserted in compliance with the SSoW at all times.

Under no circumstances is damaged cardboard to be used and it must be discarded locally.

For reference to the current, agreed York Container SSoW (See Attachment).

For reference to the Safe Systems of Work (SSoWs) for York Containers and the new design Mk2 Cardboard Sleeves (See Attachment).

1(c). York Containers – Loading Parcels of a Shoe Box Size or larger.

In previous years both Royal Mail, Tracked Customer and Amazon had concerns about the shortage of York Containers across the network and additional costs incurred by losing approximately 15% of York fill capacity when inserting Cardboard Sleeve false bases into York Containers. In line with the York Container SSoW, York Containers will be filled and stacked with parcels/packets larger than shoe box size without any form of Cardboard Sleeve or false base etc. This approach is only applied to larger items and Sleeves, Bases and Cross Members will not be removed for smaller packet items, i.e., those smaller than a shoe box size. Those packets will continue to be loaded into York Containers with either an ALP Sleeve (preferable) or a full Cardboard Sleeve with a cross-member and false base fitted. This was jointly examined and found to be the best approach.

The York Container SSoW, under the heading of ‘Approved Loads’ includes the following:- ‘loose strapped bundles and boxes which are of sufficient dimensions, that they will be retained by the load retention straps and metal container framework.’ (See Attachment).

This approach has been ergonomically tested and approved prior to concluding the York Container SSoW. It makes both safety and business sense to apply this principle for larger parcels which are not suitable for loose loading into sleeved Yorks in most cases.

1(d). York Containers – Use of Shrink-Wrap/Cling-Film

The existing agreed national policy remains as follows “There is no agreement whatsoever to use “Shrink-Wrap/Cling-Film” on York Containers under any circumstances. Also, Opsflash – CPC (2008) No 167 instructs all sites that have received new trays delivered on pallets and shrink wrapped to remove and dispose of the shrink wrap immediately. There are NO circumstances where the shrink-wrapping of Yorks is acceptable. This practice must not be allowed at any RM site.

- RSCs Rigid Stackable Container

RSCs are not intended for BAU usage inside Mail Centres and Delivery Offices and are primarily for the Distribution Centre’s and Parcel Sorting Centre network. However with a shortfall in Yorks, there may be circumstances which require flows on a contingency basis for the transfer of workflows where there is sufficient space and where risk assessment and Safe Systems of Work requirements apply. In respect of workplace transport hazards from FLTs and crush hazards etc., specific Personal Protective Equipment (PPE) regulations requirements also apply in these work environments, e.g., high visibility clothing and protective footwear. RSCs may only be used in risk controlled working environments as per the Safe Systems of Work.

- FSC Folding Stackable Containers

As Above

Safe Systems of Work (SSoW) are located on a plate on the side of the container. (See Attachment).

MCs/DOs should not receive FSCs, however, if received they should be returned to the local RDC as soon as possible.

- Cardboard RSCs/Cardboard Euro Pallet Boxes/Amazon Gaylord Pallets/ Shrink Wrapped Pallets

As originally reported in LTB 632/05 these types of containers have been successfully utilised during successive Christmas pressure periods since 2005, and were introduced to provide contingency ‘back-up’ container assets as York Container use is maximised, as opposed to using Yorks and RSCs when in short supply so these are brought into service and used during the Xmas pressure period mainly for customer use. These are used primarily in the RDC, PSC network, RM International BAU streams and used as a ‘contingency measure’ for when demand outstrips supply of Yorks and RSCs for agreed flows – as an alternative.

These variant containers are folding, heavy-duty cardboard containers with the base fixed to a standard wooden Euro Pallet.

25,000 Euro Pallet Boxes have been purchased this year and are available as a contingency back-up as an additional container type during the Christmas peak period and intended:

- For use anywhere in Royal Mail’s network and at large customer premises.

- For storage of empty bags and trays to release RSCs into the network.

- For conveyance of Customer Parcel Returns.

- For conveyance of Customer Collections.

- For conveyance of parcels within the RM network (RDCs, MCs, PSCs & Customers).

- For use in RM International BAU flows.

- For conveyance of empty bags to customers.

- For empty bags, empty trays and bags of mail.

CRSCs and Euro Pallet boxes are intended to be:

- A reusable container and serviceable for over 8 trips per usage.

- Used indoors and in the network, but NOT for external storage where they may get wet.

- Folded flat when being stored empty.

For agreed uses and safety information on CRSCs, Euro Pallet Boxes, Pallets and Amazon Gaylord Pallets loads please reference attached SSoWs.

- ‘A’ Frame Roll Containers

As originally reported in LTBs 838/06 and 840/06, 12,000 supermarket type ‘Roll Cage’ Containers were introduced in 2006 by the Royal Mail Group Procurement Operational Equipment Team, manufactured by ‘Palletower’ and ‘Cargo Pak’. They were strictly intended for internal use (inside Offices) and for storage purposes only, in order to free up much needed York Containers. Since their introduction, the number of York Containers has doubled and the limitations of these ‘Roll Cages’ have seen them become outmoded against the all-round far superior York Container. These containers have therefore and will continue to be run down, phased out and withdrawn from Royal Mail service. SSOW – (See Attachment)

For removals of the containers please contact: container.reporting@royalmail.com

- Loose Loading of Mail Bags – Christmas 2020

Further to enquiries and concerns raised by Branches and Area Safety Reps in previous years regarding possible loose loading, Royal Mail has confirmed they will be taking a number of steps to ensure that loose loading of mail should only take place in exceptional circumstances, as a last resort due to container supply shortages.

If loose loading has to occur, local CWU Reps will be consulted and the Manual Handling/Loose Loading SSOW will be adhered to.

Clear instructions have been issued by Royal Mail HQ CPC that should any service which is normally containerised have to be loose loaded, then the dispatching unit must inform the receiving unit in advance so that they can provide any additional staff resources and working arrangements which may be necessary to ensure health and safety standards are maintained.

Extract from Loose Loading Core Risk Assessment:

It is a Royal Mail goal that no manual handling task will exceed risk level 2. Mail Bags average 7kg, maximum gross weight 11kg. Lifting frequency up to 7 bags/minimum over a 30 min period (then rest). Vehicle doors are adequately maintained and must be in good working order.

Priority Services bags could exceed 11kgs but they should be clearly labelled with the weight so that special consideration can be given to lifting. NB: No Priority Services Bag exceeding 11kgs should contain more than 1 item. All equipment is used in accordance with the appropriate Safe System of Work. All staff to have received manual handling training and instruction or refresher training during the past 3 years. All staff to understand and operate the appropriate Safe System of Work. If there are any tasks that are not listed, the manager must consult the safety team for further advice. No pregnant worker or person under 18 should undertake tasks greater than risk level 1.

- Plastic Letter Trays

Last year RM purchased 1m trays which stayed in the system. Letter decline has meant Royal Mail has purchased an additional 600,000 trays this year as demand is no longer as high, these are already in production and will be delivered directly from suppliers during November and December.

- New Blue Bags for International Dispatches

2.5 million new blue bags for international dispatches have been purchased this year and will be fed into Mail Centers via direct delivery in November ready for the DSL Operation.

New RM International MB4L Bags for Automation

RM International has this year deployed a new larger blue bag for use within its Automation Streams known as the MB4L. These bags are not to be used in RM domestic postings and are designed for export only and only to be handled and used within RM International Sites.

- Pallets – Transportation, Processing, Unloading and Stacking of Pallets

This year Royal Mail has again faced an increased requirement from bulk customers to accept and process palletised loads, including shrink/stretch wrapped palletised traffic and Cardboard Pallet Boxes from Amazon known as Gaylords. The SSoWs have therefore been reviewed to ensure sufficient up to date information and instruction is available to allow Offices and managers to control safety risks for the specific tasks and ensure the correct work methods are adopted and materials handling equipment is deployed for this increasing area of work to ensure it can be completed safely. The new, updated SSoW and associated, embedded SSoWs are attached. This includes embedded documents – Pallet Truck SSoW, DDT SSoW, Palletising of Trays SSoW, and Manual Handling SSoW. (See Attachment).

- Repatriation of York Containers, ALPs, Trays and Cardboard

To ensure sites are safe and clear throughout our busiest time of year with the largest volume of containers within the network, Delivery Offices are to ensure that Container repatriations regularly take place and are returned to the agreed locations. Repatriated Yorks should be fully nested and consolidated in line with the York SSoW as well as being identified on the Office’s Yard Risk Assessment. This will ensure congestion and potential safety issues are avoided as well as ensuring Royal Mail can maintain York Container supplies to customers in order to deliver a good quality service.

We would encourage ASRs, WSR and IR Reps to report any excessive build up York Containers within their respective Delivery Offices to container.reporting@royalmail.com so that they can assist in site clearances and ensure safety and support for the operation and customer requirements.

- Repair of Faulty & Damaged Containers, Sleeves, Trays

All damaged containers must be withdrawn and repaired before being brought back into service. The following instructions relate to the repair of the individual containers:

(a) Letter Trays

- Royal Mail has an agreement with one plastics group for the recycling of RM letter trays, for which Royal Mail receives payment. For this to be cost effective AAC Ltd will only accept complete trailer loads of trays, equating to 5200 trays. This process describes the use of a collection point to ensure that trays are recycled and do not build up in offices.

- Trays must be removed from use if damaged and not suitable for use if, for example:

- There are any obvious physical defects such as breakages or holes (other than those designed).

- The tray sides or bottom are split.

- The handle is damaged e.g., split.

- The label holder is damaged in such a way as to render it unusable.

- The tray is NOT deemed damaged if only:

- The barcode or barcode clip is missing.

- The tray bottom is bowed.

- Only the corners are chipped and then only if the break does not leave a jagged or pointed edge.

- Ensure the damage sustained to trays meets the criteria described above.

All Mail Centres and Delivery Offices should have a process for identifying damaged trays and for isolating them from operational use. Delivery Offices should label the trays as damaged and send them to their local Mail Centre for consolidation and recycling. - All damaged trays should be loaded to RSCs. The trays should be nested, where possible 8 to a layer and 9 layers high, where the height of the trays does not exceed the height of the RSC sides. RSCs of damaged trays should be labelled as shown below and then sent to the local RDC for onward movement to NDC. Spare capacity on existing runs only should be utilised.

DAMAGED TRAYS:

SEND TO AAC via NDC

- NDC to consolidate the RSCs of damaged trays and, when a trailer is loaded to capacity, forwards them to One 51 Plastic.

(b) York Containers

Examples of damage:

- Sharp, jagged or pointed hazards.

- Anything, which prevents proper assembly.

- Anything, which prevents proper movement.

- Temporary or amateur repairs.

- Broken welds.

- Excessive corrosion.

- Damaged or missing wheels.

- Missing wheel retaining nuts, pins or clips.

- Poor brake operation.

- Damaged or defective towing arrangements.

- Missing or damaged straps or clips.

The repair process is as follows:

- A number of sites have been nominated to receive a scheduled visit by a York repair team (currently RMP&FS).

- Some sites also act as a consolidation site looking after a catchment area of other offices. For example, SDC in Wishaw receives all of the damaged/strapless Yorks in Scotland and Northern Ireland.

- A contact at each site has been developed and a location for the storage and repair of Yorks identified.

- Each Thursday a count of damaged Yorks is submitted by each site to the Royal Mail mhe_cpc e-mail inbox and the figures are used to plan a schedule for the following week’s site visits. Some offices may have a team that visits every day whilst others will be visited by mobile teams as required. The minimum requirement is that there be 50 Yorks needing repair on site.

- A repairer can replace anything up to 100 straps per day but, if there are structural repairs also needing to be done, the overall number can reduce substantially. The repairer will check each damaged York for other possible problems and does not solely rely on the fault noted by Royal Mail staff.

Damaged Yorks may be moved, on existing services, from non-repairing sites to a consolidation site (see repair process above) to await repair. Damaged Yorks should be labelled accordingly so that the receiving site is aware.

Damaged Yorks must not, however, be used to form part of a movement order to another site and should never be sent to a customer. Neither should damaged Yorks knowingly be used to convey mail through the network.

Some straps have given the appearance of losing their elasticity but tests have been carried out at the manufacturer and replicated by our engineers in Swindon and the results show that this does not affect load retention or the safety of the York. It is not, therefore, necessary to replace such straps.

Short Strap repairs, can be carried out locally at any site for more information contact container.reporting@royalmail.com

(c) RSC and FSC

- Examples of damage to an RSC/FSC are as follows;

– Sharp, jagged or pointed hazards.

– Anything which prevents proper assembly or movement.

– Temporary or amateur repairs.

– Broken welds.

– Broken side wires bent inwards or outwards.

– Excessive corrosion.

– Mis-aligned feet or spigots which hinder stacking.

- In these circumstances, an ‘Out of Service’ label must be attached and the nature of the problem noted on the label.

- Damaged RSCs/FSC’s should be moved to a designated area to await repair. They may only be stacked if the uprights are intact and make contact with the RSC/FSC above at all 4 corners. They may not be stacked if to do so would leave an unstable stack. If in doubt – DO NOT STACK.

- Damaged RSCs/FSC’s must be forwarded to NDC for onward movement to MK Stores for repair. Movements of damaged RSCs should be agreed with the local Container Equipment Manager beforehand.

(d) Auto Levelling Packet Sleeves

- A minimum of 25 sleeves will be presented for repair in a single consignment. Sleeves are to be packed in Rigid Stackable Containers (each containing 25 sleeves).

- Clearly labelled damaged RSCs are to be returned to SWDC for onward movement back to the manufacturer Jacon.

(e) York Cardboard Sleeves

- Cardboard Sleeves are not repairable. Any damaged sleeves must be disposed of by local arrangement.

- Any re-usable parts of cardboard sleeves must be returned to Amazon; whether by direct transfer or via the nearest RDC.

- Cardboard inserts to be stored/transferred in York’s or palletised on at Regional Distribution Centre’s using good pallets.

- If held/stored onsite ahead of transfer they must be kept under cover or protected from the weather.

- All component parts must be in good order (certainly not water damaged or torn) and ready to use. Any not meeting these criteria should be disposed of locally.

- Yorks must be individually packed i.e., no mixed component parts please. Yorks to separately contain X Member/Sides/Bases which must be stacked neatly.

- Any transfers arriving at Amazon that do not meet these criteria may be refused by the Amazon Team.

(f) Cardboard RSCs/Euro Pallet Boxes

Any damage needs to be checked. The following damage would render the Cardboard RSC unusable:

- Water damaged/wet cardboard.

- Tears greater than 25%/¼ of the length of any one side or along any seam.

- Tears in 2 adjoining corners of the tray or lid.

- Staples in the seam undone with exposed points.

- Broken Pallet Base such that the wooden planks are broken or the corner blocks are damaged such that they would not support a load.

The following would not necessarily render the Cardboard RSC/Euro Pallet Boxes unusable:

- Small holes in the side walls, for example made by fork lift tines.

- Small tears, i.e., less than 25%/¼ of the length of any one side or along any seam.

- One tear in the corner of the tray or lid.

If there is any doubt as to the safe condition of the asset, then it must be considered damaged. Any damage which renders the sleeve unusable needs to be reported and the damaged part (i.e., the lid, sleeve or tray) marked with a cross from a thick marker pen. Only the damaged part needs to be marked as the undamaged parts may be used as spares.

Transport and transfer equipment must meet the receiving customer’s safety requirements.

(g) Wheeled Container Repair Process including Mini Yorks (Other than York Containers)

The following process should be used to keep wheeled containers functional:

- When a wheeled container (other than a York) is found to be faulty, remove it from operational service and label it accordingly.

- Log the fault with the Properties & Facilities Helpdesk on 0870 850 1000, who will give a reference number. The Helpdesk will then contact RMP&FS, who allocates the work to the local coordinator. A RMP&FS engineer then plans and completes the repair.

- If the repair is not economical, the engineer condemns the equipment and advises the Unit Manager. The Unit Manager then decides if they want it replaced, and completes a Requisition Form ECF01 and sends it to the Asset Support Team.

- When the repair is completed, RMP&FS invoice through the Inter Business Agreement, which is funded from the central assets budget. Area budgets are not affected.

(h) General note on containers:

If there are any surplus containers on site that are not damaged and you are unsure of where to send them, you should consult your Regional Head of Assets for Yorks, Trays and Sleeves or your Container Equipment Manager for RSCs.

- Contacts & Phone Numbers – IMPORTANT

Should Area Safety Representatives wish to discuss any issues or questions in relation to Container Control or Container Equipment, the following field managers can be contacted for all Royal Mail Container related issues:-

National Team Contacts

National Asset Supply Chain Manager Gary Yeo – 07872 636537

National Container Supply & MHE Manager Ian MacDonald – 07436 560875

Container Manager North Clare Smith – 07872816461

Belfast, SDC, Edinburgh, Perth, Inverness and

Aberdeen, Warrington, Chester, NWDC, NWPSC

Tyneside, Darlington, Preston, Chorley,

Carlisle, Manchester, Stockport, Leeds,

Bradford, York, YDC, Sheffield, Doncaster and

Hull, Nottingham, NEPSC, East Midlands Airport

Crewe, Shrewsbury

Container Manager South Sid Rajan – 07802 921737

HCN, NHCDC, Greenford, PRDC, Jubilee, Guilford and

Woking, Derby, Coventry,

Leicester, Peterborough, Cambridge, Norwich and Ipswich

Chelmsford, Southend, Medway, SEDC, Canterbury,

Tonbridge, Croydon, Gatwick, London Central,

South Warwick, Victoria, Romford and Whitechapel

Container Manager Amazon (All Sites) Chris Rogers – 07860 172019

Container Manager International Nalin Mandalia – 07715480197

HWDC and LAMU, Atherstone international

- Health & Safety Processes

From a Health and Safety point of view the CWU Health, Safety & Environment Department will continue our joint work with Gary Yeo RM National Asset Supply Chain Manager and Ian MacDonald RM National Container Supply & MHE Manager along with the SHE (Safety, Health and Environment) Team and the RMPFS Property Safety and Compliance Team to monitor health and safety throughout the Christmas Operations.

- IR Aspects

The IR aspects of the Christmas pressure period are dealt with by the Postal Department. All Operational enquiries should be addressed to the appropriate Postal Department Operational Officer.

Attachments:

- Manual Pallet Truck (MPT) SSOW v1.2

- York and Mini -York Safe System of Work v3.2

- Pallets SSOW v1

- Shrink-Wrapping Pallets v1.0

- Cardboard Sleeve York Container Additional Requirements SSOW v1.1

- Transport of Yorks and RSCs SSOW v1.3

- MK3 York Bases (COVID)

- Cardboard RSC and Euro Pallet Box SSOW v1.2

Yours sincerely

Dave Joyce

National Health, Safety & Environment Officer

Cardboard RSC and Euro Pallet Box SSOW v1.2

Cardboard Sleeve York Container Additional Requirements SSoW v1.1

Manual Pallet Truck (MPT) SSoW_v1.2